Isantya Esiphezulu Ngokuzenzekelayo Ngokupheleleyo Umgca Wemveliso Opheleleyo Wokuhlamba Indlu yangasese Encinci Isikali Esincinci Iphepha Lokusonga Iphepha Lokwenza Umatshini Ixabiso ETshayina

Lo matshini wokubuyisela iphepha lendlu yangasese unokubuyisela umva i-roll enkulu yephepha lendlu yangasese ibe ziidayamitha ezahlukeneyo ezincinci ngaphandle kokutshintsha ububanzi bayo. Ububanzi kunye nokuqina kwe-rolls zendlu yangasese ezigqityiweyo kunokulungiswa ngokulula ngokutshintsha useto kwiphaneli yokulawula, kwaye ii-rolls zephepha eziphumayo zilungele ukusika.

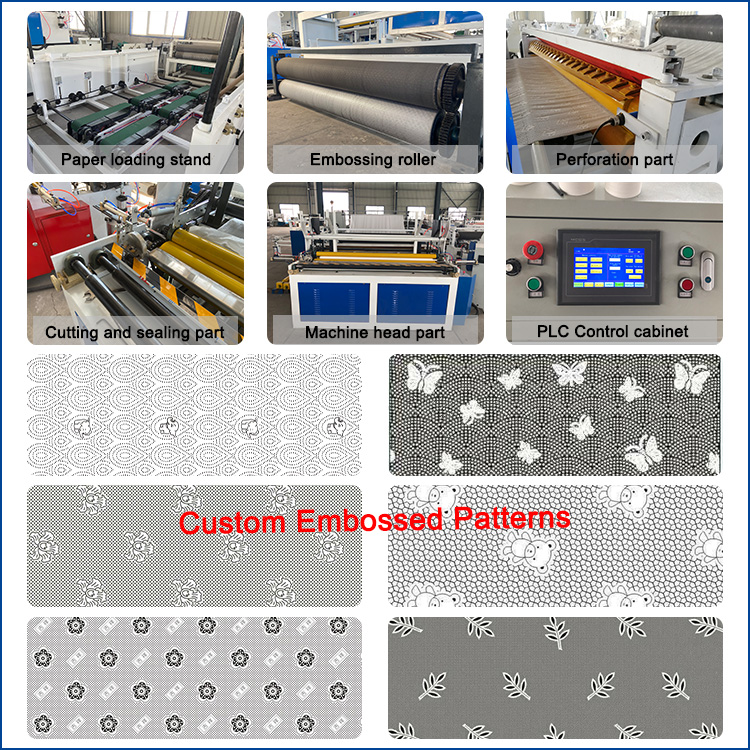

Le sixhobo sokubuyisela iphepha lendlu yangasese sisebenzisa umgaqo wesantya ongenamagxathu wokuguqulwa kwe-AC frequency, onokusebenza ngokuzinzileyo ngelixa abathengi betshintsha isantya sawo.

Lo matshini unenkqubo ye-PLC kunye nephaneli yokulawula yeHuman Machine Interface ukuze umntu omnye akwazi ukuyisebenzisa ngokulula. Ngumatshini ofanelekileyo kwisityalo esincinci sokwenza imveliso yephepha langasese.

| Imodeli | YB-1880 | YB-3000 |

| Ububanzi bomqulu omkhulu (mm) | ≦2200mm | ≦3000mm |

| Ubungakanani obuphambili bephepha elingavuthwanga | 76.2mm | |

| Ububanzi bemveliso egqityiweyo | 90-250mm (Obunye ubungakanani obufunekayo) | |

| Ubungakanani obuphambili bemveliso egqityiweyo | Φ 32-50mm | |

| Umgama wokugqobhoza | 100-150mm (Obunye ubungakanani obufunekayo) | |

| Ukusika nokuvala umsila | ukusika ngokubanzi, umsila uvalwe kakuhle kwaye uthembekile; Itanki yokugcina yokugcina iglu | |

| Ukuqhuba okuphambili | Ulawulo lwesantya sokuguqulwa kwamaza 7.5-15KW 380V,50HZ | |

| Ityhubhu engundoqo: | Ukulayisha okuzenzekelayo kwe-core | |

| Iphiko lokugqobhoza | Iiblade ezi-6, 110mm | |

| Ukuseta iiparameter | I-HMI | |

| Isantya somatshini | 0-300m/ngomzuzu | |

| Iyunithi yokuhombisa | Intsimbi ukuya kwirabha/intsimbi ukuya kwintsimbi/intsimbi ukuya kwiboya | |

| Inkqubo yomoya | I-3HP air compressor, uxinzelelo oluncinci 5kg/cm2pa (inikezelwa ngumsebenzisi) | |

| Ukuqhuba ngoomatshini | Ukuqhuba ngebhokisi yegiya engenazitebhisi | |

| Ubunzima | 3T | 4T |

| Iyunithi yokuLamination | Inga-odolwa | |

Ukutya okuzenzekelayo okune-roller ezine→ukudlulisa okuhambelanayo→ukuhombisa→ukubhoboza→ukujika okuzenzakalelayo→ukusika→ukupakisha→ukutywina.

1. Ukubuyisela umva---Injongo ephambili yomatshini wokubuyisela umva iphepha lendlu yangasese kukucubungula iphepha elikhulu elinomngxuma libe ngumcu omde wephepha lendlu yangasese.

2. Sika iphepha---Iphepha elide elisikwe ngumsiki wephepha lisikwa libe ziimveliso ezigqityiweyo zobude obungaphelelanga

ezifunwa ngumthengi.

3. Ukupakisha---Ukupakisha kungapakishwa kumatshini wokupakisha okanye kusongelwe ngesandla, kwaye iimveliso ezigqityiweyo zephepha langasese zipakishwa kwaye zivalwe ngumatshini wokuvala.

1. Ukusebenzisa ikhompyutha ye-PLC ukucwangcisa iphepha eligqityiweyo kwinkqubo yokubuyisela umva ukuze kufezekiswe ukuqina nokukhululeka kokuqina okwahlukileyo ukusombulula ukukhululeka kwemveliso egqityiweyo ngenxa yokugcina ixesha elide.

2. Umatshini wokubuyisela umva ozenzekelayo unokukhetha i-embossing enamacala amabini, i-gluing compound, enokwenza iphepha lithambe ngakumbi kune-embossing enamacala amabini, isiphumo seemveliso ezigqityiweyo ezinamacala amabini siyafana, kwaye umaleko ngamnye wephepha awusasazeki xa usetyenziswa, ngakumbi ufanelekile ukucutshungulwa.

3. Lo matshini uxhotyiswe ngokucubungula iphepha langasese elingenanto yakwenza neliqinileyo, elinokutshintshatshintsha phakathi kweemveliso ngoko nangoko, kwaye linokukhethwa ngokweemfuno zomsebenzisi.

4. Ukusika ngokuzenzekelayo, ukutshiza ngeglu, ukutywina, kunye nokufunxa kwenziwa ngaxeshanye, ukuze kungabikho lahleko yephepha xa iphepha eliqengqelekayo lisikwa kwisarha yebhendi kwaye lipakishwe, nto leyo ephucula kakhulu ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso egqityiweyo. Kulula ukuyisebenzisa.

5. Ukondla ngebhanti yomoya, i-reel ephindwe kabini kunye ne-axis nganye yephepha lokuqala inendlela yokulungisa uxinzelelo ezimeleyo

-

Umatshini wokwenza iphepha le-napkin tissue eliphindwe kane elinesiqingatha

-

Iphepha le-Egg Trey yeBamboo eNcinci yokwenza umatshini we-auto ...

-

Umatshini wokusika ibhendi ye-automati ozenzekelayo ...

-

Iphepha elincinci elizenzekelayo elilahlwayo lokuvelisa ...

-

Umbhobho womatshini wokwenza i-Spiral Paper Core ozenzekelayo ...

-

Umatshini Wokwenza Iphepha Lethishu Iseti Epheleleyo Yemveliso ...