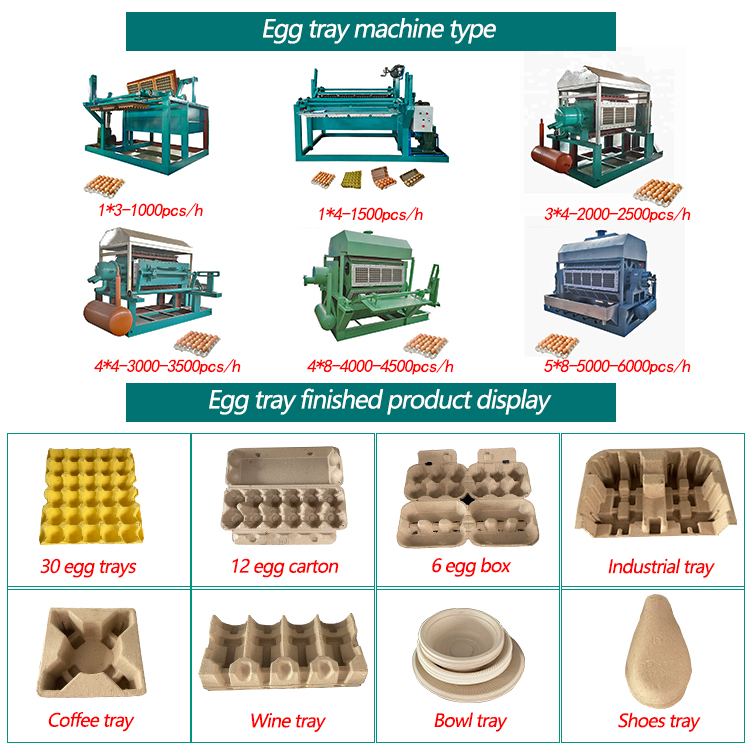

1. Umgca wemveliso yePulp Moulding waziwa njengomgca wetreyi yamaqanda osetyenziswa kakhulu kwitreyi yamaqanda emveliso.

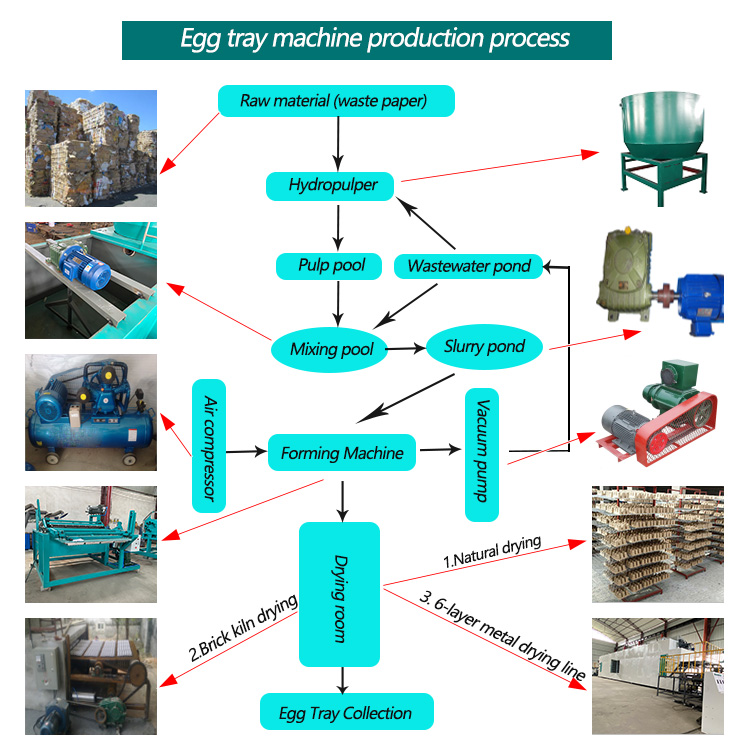

2. Umgca wemveliso yePulp Moulding, osebenzisa iphepha elilahliweyo, ikhadibhodi, izinto eziseleyo zomatshini wephepha, nge-hydraulic pulper, umxube owenza i-pulp ethile exineneyo, kwaye i-pulp ifunxwa yi-vacuum ye-moulding ekhethekileyo yesinyithi ukuze ibe ziimveliso ezimanzi, ngokomisa, nangokubumba ukuze ibe ziimveliso ezigqityiweyo.

3. Ukulungiswa kwePulp Moulding Line kusebenzisa amanzi asetyenzisiweyo kwaye akukhokeleli kungcoliseko lwamanzi okanye lomoya. Iimveliso zokupakisha ezigqityiweyo zingaphinda zisetyenziswe emva kokuba zisetyenzisiwe ekugcineni, ekuthuthweni, nasekuthengisweni. Emva kokuziqhekeza, kulula ukuzibolisa njengephepha, nokuba zilahlwe kwindawo yendalo.

4. Imigca yemveliso yokubumba i-pulp ezenzekelayo ingaba yimveliso enkulu yesikhongozeli sokutya esahlukeneyo, itreyi yamaqanda, iibhokisi zesidlo sasemini njalo njalo.

| Imodeli yoMshini | 1*3/1*4 | 3*4/4*4 | 4*8/5*8 | 5*12/6*8 |

| Isivuno (p/h) | 1000-1500 | 2500-3000 | 4000-6000 | 6000-7000 |

| Iphepha leNkunkuma (kg/h) | 80-120 | 160-240 | 320-400 | 480-560 |

| Amanzi (kg/h) | 160-240 | 320-480 | 600-750 | 900-1050 |

| Umbane (kw/h) | 36-37 | 58-78 | 80-85 | 90-100 |

| Indawo yokusebenzela | 45-80 | 80-100 | 100-140 | 180-250 |

| Indawo yokomisa | Akukho mfuneko | 216 | 216-238 | 260-300 |

I-servo motor drive echanekileyo kakhulu, ukusebenza kakuhle kunye nomgca wokomisa owonga amandla.

1, Sebenzisa i-servo motor yokunciphisa ngokuchanekileyo ukwenza nokudlulisa ukuqinisekisa ukusebenza ngokukhawuleza.

2, Sebenzisa i-absolute encoder ukuze ufumane ukulungiswa okuchanekileyo.

3, Ukusetyenziswa kwesakhiwo sesangqa esiqinileyo nesinamandla se-bronze casting kulungele ngakumbi inkqubo yokukhupha amanzi kwimveliso.

4, Ukusetyenziswa kwesakhiwo soomatshini ukuqinisekisa ukuba isikhunta sivaleka ngokulinganayo kumacala omabini.

5, Umthamo omkhulu; Umthamo wamanzi uphantsi; Gcina iindleko zokomisa.

1. Inkqubo yokutsalwa kwesisu

2. Inkqubo yokwenza

3. Inkqubo yokomisa

(3) Umgca omtsha wokomisa oneeleya ezininzi: Umgca wokomisa wesinyithi oneeleya ezi-6 unokonga amandla angaphezu kwama-30%

4. Ukupakisha okuncedisiweyo kwemveliso egqityiweyo

(2) Umthengisi

(3) Umthuthi wokudlulisa

-

Iphepha le-Egg Trey yeBamboo eNcinci yokwenza umatshini we-auto ...

-

Iphepha lenkunkuma lokurisayikilisha iqanda ibhokisi yebhokisi yeqanda itreyi yeqanda ...

-

Umatshini wokwenza itreyi yamaqanda i-YB-1*3 1000pcs/h ye-bu...

-

Umgca wemveliso wetreyi yeqanda yephepha elizenzekelayo / ...

-

Umatshini Wokwenza I-Egg Tray Pulp Molding for Small ...

-

Iphepha lenkunkuma elizenzekelayo le-pulp egg tray yokwenza i-mach ...